- Warm tip: When purchasing the authentic Guangzhou Zhujiang cable, please look for the "Kapok" sign.

- Warm tip: When purchasing the authentic Guangzhou Zhujiang cable, please look for the "Kapok" sign.

Knowledge of fire prevention in cable laying

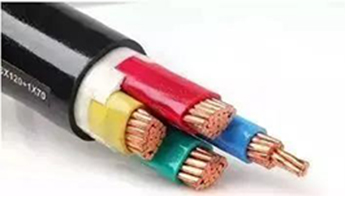

First, choose flame retardant wire and cable

Fire prevention mechanism of flame retardant wire and cable: under the thermal action of combustion reaction, the thermal decomposition of flame retardant located in the condensed phase absorbs heat, which slows down the temperature rise in the condensed phase and delays the thermal decomposition rate of materials. At the same time, the release of chain reaction free radical blockers, which interrupts the branching of flame and chain reaction, slows down the gas reaction speed and prevents the temperature rise in the condensed phase, so as to achieve fire prevention effect.

Classification and selection of flame retardant wire and cable: flame retardant cable mainly includes ordinary flame retardant wire and cable, halogen free and low smoke flame retardant cable, low halogen and low smoke flame retardant cable, refractory cable, these products are different in manufacturing technology, performance characteristics, application range is different.

Two, scientific design and installation

Plugging: Fireproof plugging is the use of fireproof plugging material to plug the gap at the crossing of the cable to prevent the cable from burning. The connection between cable trench and electrical tray, box, cabinet, partition wall, floor holes, etc., should be flame retardant sealing. The cable fire door should be closed for a long time, the gap between the cable fire proof board and the cable trench cover should be closed, and the cable laying dense place should be sealed with soft plugging material;

Separation: fireproof partition wall can be long cable tunnel, cable channel divided into small sections, the fire interval can be reduced, can be used refractory partition, aluminum silicate fiber felt, fireproof plugging material, fireproof coating, etc. Fire partition wall made of slag cotton, in the tunnel and fire door matching use;

Coating: Brush fire retardant coating can avoid cable fire delay burning, fire retardant belt construction is convenient, not easy to fall off, strong adaptability, cheap price. In the cable into the cabinet to the terminal head part, in the fire partition wall on both sides of the 2 to 3 meters of the area of all the cables painted twice or coated with fire retardant tape.

Three, set up fire prevention facilities

Set up the fire alarm system: according to the actual situation, choose the appropriate alarm probe and the alarm system suitable for the characteristics of the cable layer. At present, the linear (or cable type) temperature detector is widely used in the cable trench and pipeline well;

High-pressure water spray fire suppression: In areas with dense cable corridors and cables, high-pressure water spray fire suppression should be adopted. In order to make the water spray fire suppression play its role timely and effectively, a highly sensitive monitoring and control system should be equipped.

Strengthen the ventilation of the cable layer (well) : by taking advantage of natural ventilation conditions, air vents should be set near the external wall of the cable layer as far as possible. Meanwhile, a mechanical smoke exhaust system with uninterrupted power supply should also be established, so as to open the smoke exhaust fan through automatic alarm in the early stage of the fire.

Iv. Standardize daily management

Keep in good running condition: prevent cable short circuit and open arc fire due to cable internal insulation defects, aging, moisture, damage and other cable faults, timely discover poorly insulated cables, and remove them from operation;

Maintain a good operating environment: it is strictly prohibited that waste gas and waste water from the thermal system flow into the cable ditch and cable tunnel;

Strengthen the monitoring and management of the cable head: the cable head is the weak link of cable insulation affected by many factors. The power cable terminal and middle joint placed in the cable trench, cable tunnel, cable trough box and cable sandwich must be registered and recorded, strengthen supervision and avoid the hot fire of the cable hair in operation.

Indicate: This article is reproduced network resources, such as copyright infringement, please contact the administrator to delete!

Prev:Already the first

Next:Already the last one

.png)

陕公网安备 61040202000668号

陕公网安备 61040202000668号